- Home

- About Us

- Our Services

- PVC Conduit Pipe Making Machine

- Extruder Machine

- PVC Conduit Pipe Making

- PVC Edge Banding Tape Making Machine

- Rigid PVC Pipe Plant

- Temprature Control Unit

- Scrap Grinder

- Soft Pvc Tubing Plant

- Slotting Machine

- Socket Machine

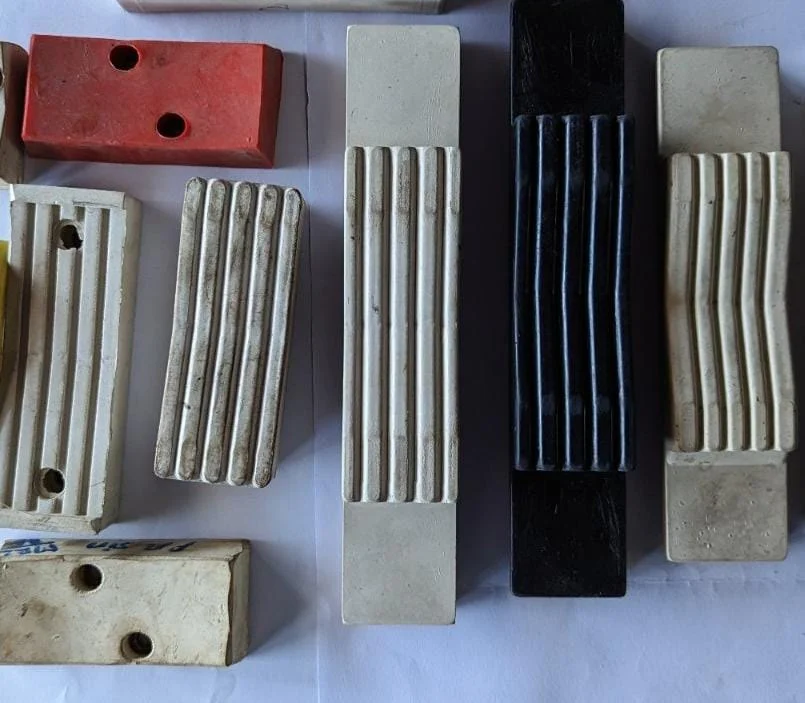

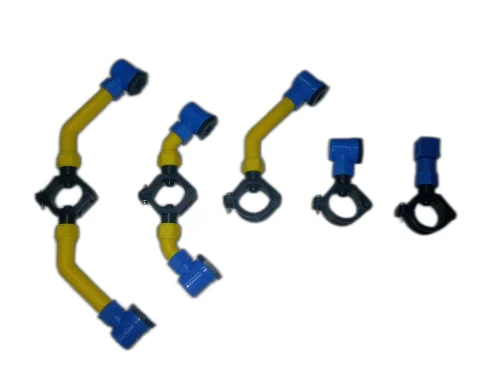

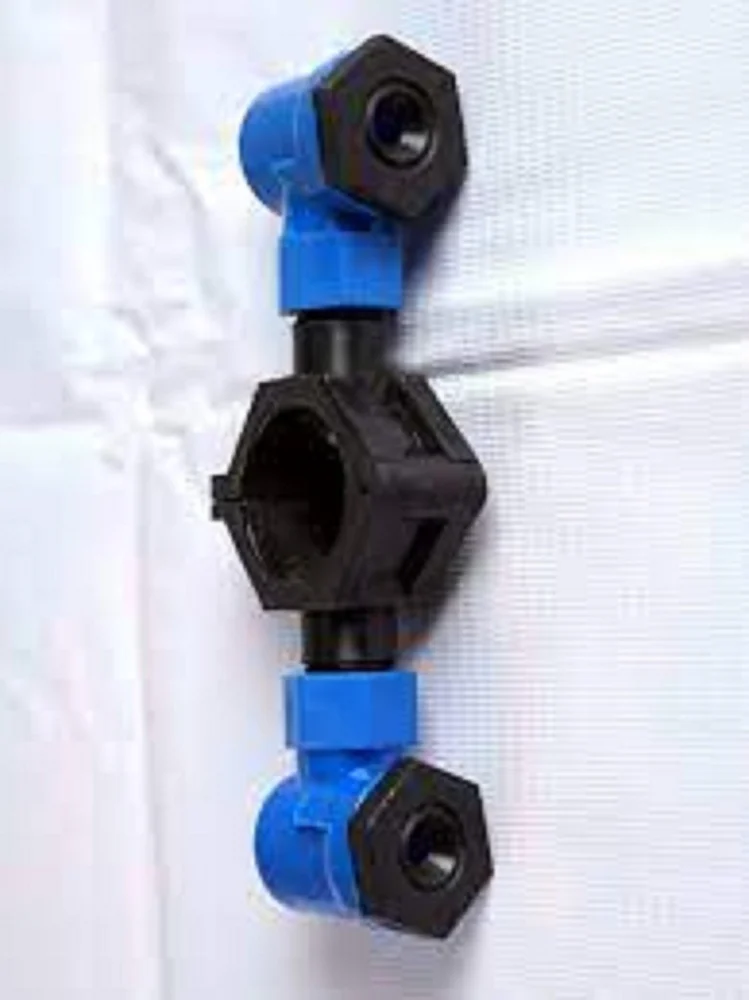

- Spare Parts

- Bio Gas Extruder Machine

- Plastic Pipe Manufacturing Plant

- Mixing Machine

- PVC Palletizing Plant

- PVC Tubing Machine

- Threading Machine

- Pulverizer Machine

- Extrusion Rpvc Pipe

- Sheet Extrsion Line

- Gallery

- Contact Us